Leistungen

Werkzeugbau

- Werkzeugplanung

- Konstruktion (extern)

- Werkzeugbau (extern)

- Instandhaltung

Kunststofftechnik

- Kunststoffspritzguss

- 12 Maschinen ( 20 to – 250 to Zuhaltekraft)

- Manuelle und maschinelle Nachbearbeitung

- < 1 Gramm – 700 Gramm Spritzgewicht

- Baugruppenmontage

- Kunststoffveredelungen

- Metallumspritzung

Kunststoffe die wir verarbeiten

- Polyamide, verstärkt und unverstärkt (PA6, PA6.6, glasfaserverstärkte)

- Polyoxymethylen (POM, POM-C, POM-H, glasfaserverstärkte)

- Acrylnitril-Butadien-Styrol-Copolymer (ABS)

- Polycarbonat (PC)

- Polycarbonat / Acrylnitril-Butadien-Styrol-Copolymer (PC/ABS)

- Polypropylen (PP), verstärkt (z.B. PPTV) und unverstärkt

- Elastomere (TPE, TPU)

- Polystyrol (PS), glasklar sowie High Impact (HIPS)

- Polyethylen (HDPE, LDPE)

Weitere Dienstleistungen

Kunststoffveredelung:

- Verchromen

- Schleifen

- Tampondruck

- Bekleben

Produktionsverlagerung

Sie haben bereits ein Spritzgusswerkzeug, wollen aber den Lieferanten wechseln oder ein Gegenangebot erhalten? Dann zögern Sie nicht und übermitteln uns Ihre Anfrage.

Neuproduktion

Sie wollen Ihrer Idee Form verleihen? Dann freuen wir uns auf Ihre Anfrage. Ihre Daten werden streng vertraulich behandelt.

Wenn Ihre Idee in Kunststoff realisierbar ist, stehen wir Ihnen kompetent zur Seite!

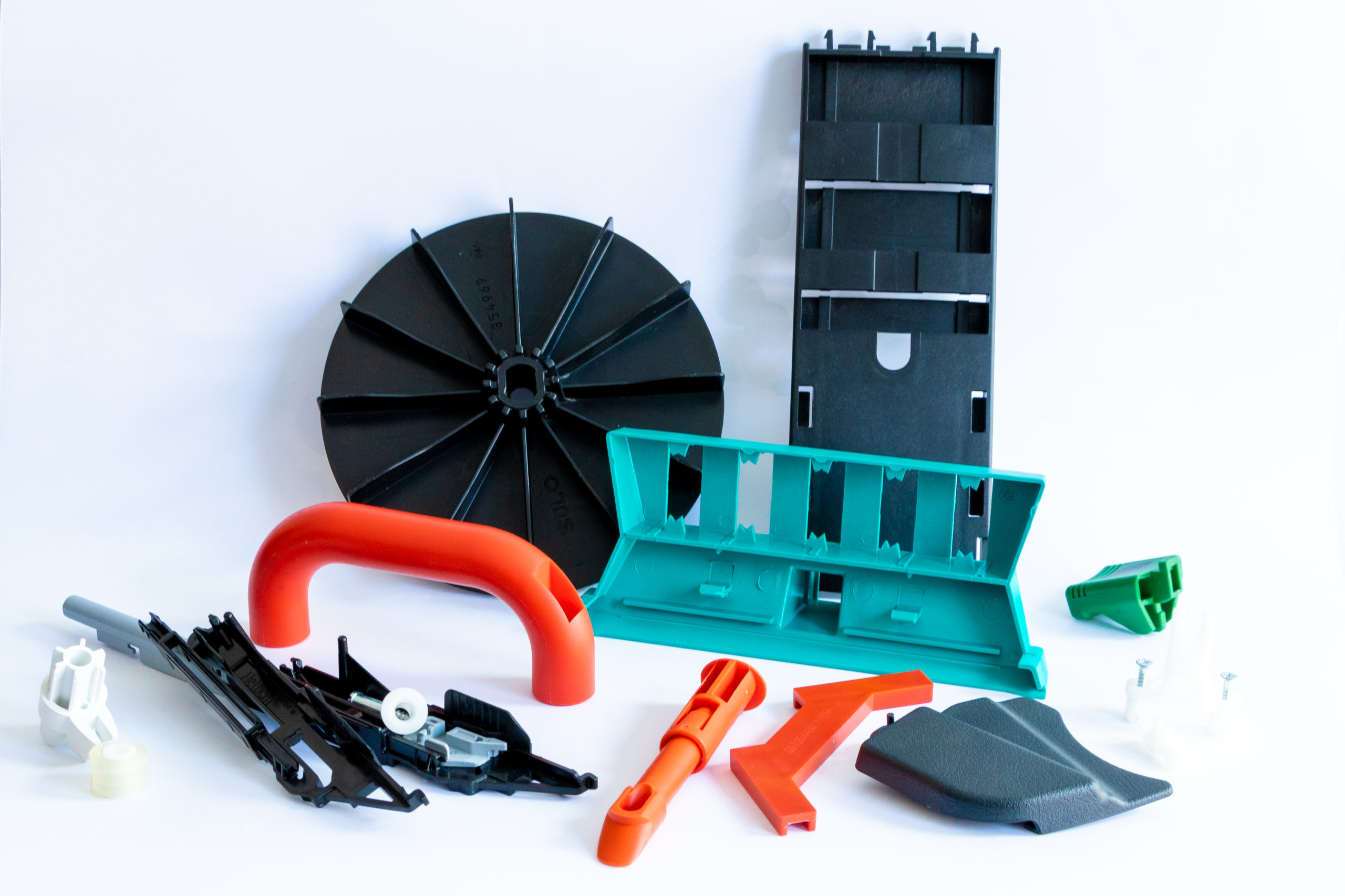

Unsere bisherigen Arbeiten

Werbeartikel

technische Kunststoffteile

Schellen

technische Kunststoffteile

technische Kunststoffteile

technische Kunststoffteile

technische Kunststoffteile

technische Kunststoffteile

technische Kunststoffteile

technische Kunststoffteile

Qualität ist uns wichtig

Qualität beginnt bei uns mit einem ausführlichem Erstgespräch. Ist Ihre Idee im Kunststoffspritzguss umsetzbar, beginnt unsere Arbeit. Wir setzen Ihre Idee in ein 3D Modell um und besprechen mit Ihnen gemeinsam die Herausforderungen die bei der Produktion bevorstehen sowie den aus unserer Sicht passenden Rohstoff. Hier besteht bereits die Möglichkeit, dass wir Ihnen ein Muster im 3D Druck herstellen lassen.

Ein perfektes Spirtzgussergebnis kann nur mit einem optimalem Spritzgusswerkzeug erreicht werden. Dieses konstruieren wir für Sie und besprechen mit Ihnen unsere gewählte Bauweise.

In dieser Phase modellieren wir den optimalen und wirtschaftlichsten Produktionsprozess, legen mit Ihnen die Verpackungsweise fest und bestimmen die Punkte der Qualitätssicherung. Erst ein reibungsloser Ablauf der genannten Punkte führt zu einem Ergebnis, welches Sie überzeugen wird.

Testen und fordern Sie uns.

Für Anfragen:

- Am Hasselbruch 7

32107 Bad Salzuflen - +49 (0) 5208 91 22 0

- info@hoffmann-werkzeugbau.de